|

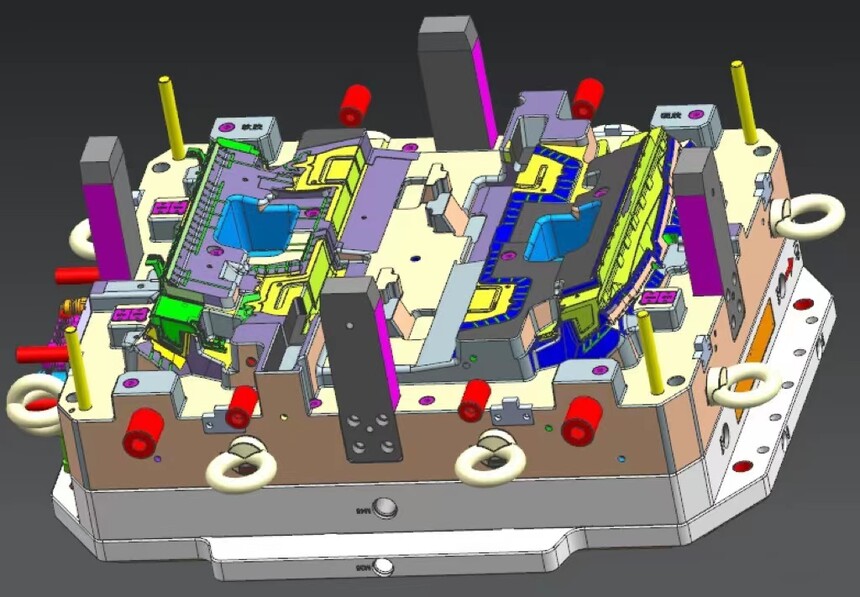

Design Points of Injection Mold Positioning System

The Role of the Injection Mold Positioning SystemThe role of the injection mold positioning system is mainly to ensure the precise positioning of the movable and fixed molds during mold clamping and injection molding, to share the side pressure on the guide pillars, to improve the rigidity and matching accuracy of the mold, and to reduce mold clamping and injection molding. The error minimizes the friction of the inner mold insert, helping the mold not to deform due to the expansion force during injection molding, thereby improving the life of the mold. The larger the mold positioning size and the more the quantity, the better the effect. When the mold is not equipped with a positioning system, the guide post and guide sleeve also act as a positioning mechanism. But strictly speaking, the role of the guide post and guide sleeve is mainly to guide, if it is also subjected to lateral pressure, its life will be seriously affected. Classification of Injection Mold Positioning SystemThe injection mold positioning system can be divided into two categories: positioning between A and B plates and internal mold insert positioning according to its installation position.

The positioning system between A and B plates is often used in large-scale mold bases (more than 400mm in mold width), which bears the lateral pressure of the mold during production, and improves the matching accuracy and production life of the mold. This system also includes a cone positioning block, cone positioning column, and side lock, and the formwork itself is positioned. 1.Cone positioning block. Assembled between boards A and B, the number used is 4, and the symmetrical or diagonal arrangement is the best. The inclination angle of the two slopes of the conical positioning block is 5°~10°. 2.Conical positioning column. The assembly position, function and use occasions of the cone positioning column are the same as the cone positioning block, and the number is 2~4. 3.Side lock. Side locks are assembled on the four sides of the mold and hidden in the formwork to prevent damage or crushing. There are two kinds of side locks: cone lock and body lock. It is often used in large molds or precision molds to improve the matching accuracy of the movable and fixed molds A and B plates and the overall rigidity of the mold. 4.The original positioning of the formwork. Cone positioning blocks and conical positioning columns are commonly used positioning structures, but for large molds, they have to bear. When the lateral force is large, the original positioning effect of the formwork is generally the best.

The Injection Mold Positioning System between the inner mold inserts is also called the inner mold pipe position. It is usually designed on the four corners of the inner mold inserts. The integral positioning effect is good. This structure is often used in precision molds, and the parting surface is a complex curved surface, or inclined molds and plastic parts are seriously asymmetrical, and molds with large lateral force components will be generated in injection molding. The size of the positioning angle of the inner mold insert ca n be taken according to the length of the insert:

What are the commonly used positioning methods for injection molds?

The above five positioning methods are commonly used in injection molds. If you are interested in producing molds and developing your new projects, do not hesitate to contact us, we will have a professional team to provide you with high-quality services at any time! |