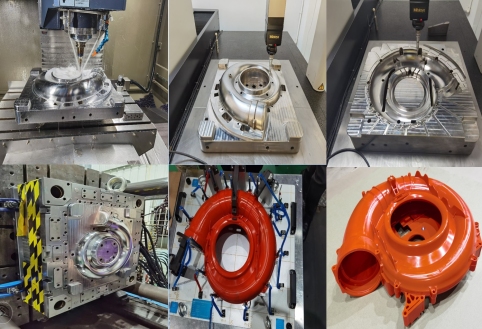

Mold Manufacturing

What is our Mold manufacturing service ?

We are professional in manufacturing Plastic Injection Mold. With years of hardworking and continuous development, we have gained widespread recognition for producing high-quality tools for the most-demanding applications in Automotive, Consumer electronics, Home appliances, Industrial products and Medical equipment etc.

Type of mold we have made

- Single and multi-cavity molds

- Cold and hot runner tools

- Double injection moldsInsert overmolding

- Reverse molding (injection and ejection on one mold half)

- Automotive moldsHome appliance molds

- Consumer electronics molds

- Mini moldsPrototype tools

- Die casting tools

Plastic Injection Molding

In house tooling and molding service

KSMOLDS provides quick-turn thermoplastic injection molding often used for prototyping, bridge tooling and short-run manufacturing up to 10,000+ parts. Our injection molding tools allow us to create parts from simple to complex with short lead times. We provide injection molding tools in aluminum, P20, H13, NAK80 and many other tool steels.

What is Plastic Injection Molding ?

Plastic injection molding involves melting granular plastic pellets into a liquid form and then compressing this liquid into the empty cavity of a mold tool. The plastic will retain the shape of the mold as well as the surface texture of the walls of the cavity. After an optimized injection and cooling phase, the now solidified plastic part is ejected and the molding cycle is repeated. This molding cycle can take from as little as a few seconds to several minutes depending upon part size, molding resin and part design.

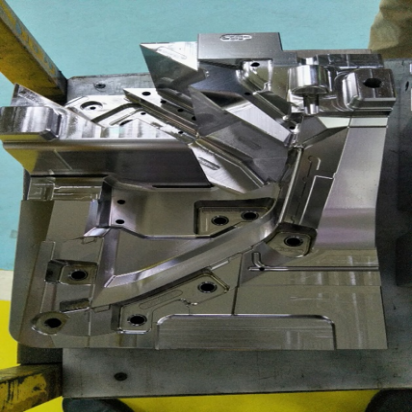

Custom Mold Components

Custom Mold Components manufacturing service for tool maker companies

We supply Custom Mold Components such as Mold Inserts, mold sliders, lifters, core and cavity blocks, ejector pins, with DHL or TNT delivery just take 3 days to your company worldwide. With our experience and the good tolerance parts we provide you can easily assemble in house.

What is the benefit of ordering custom mold components?

1.Enlarge your capacity

You can order mold base and standard parts in your country, and we made the inserts and spare parts. You just need to assembly all the parts arrive.

2.Save cost

You can save cost by order mold components in China.

3.Flexible

You can assemble and trial the tool in your company with you customers.

Why ordering Mold Components from us?

- High quality insurance. All parts be fully inspected in each stage of process. Inspection report will be provide with everything correct and acccurate.

- Mature technology with precision equipment. Our parts will prefectly suit your needs, can be assembled immediately without fitting.

- Fastest deliver time, as soon as 15 days tooling +3 days deliver for whole set of mold parts.

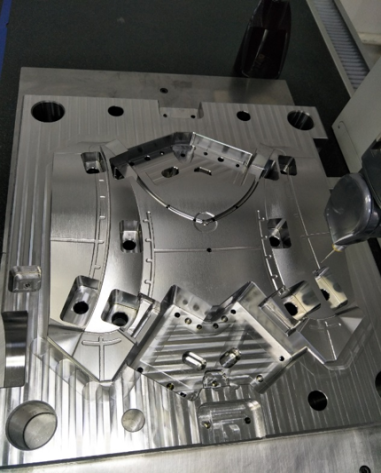

CNC Machining Service

CNC Milling

CNC Milling is used to apply a machined surface finish on engineering-grade plastic or metal for creating complex 3D shapes. KSMODLS use high precision CNC machining centers with quick-change tooling. Our programer toolpaths the digital part design to our CNC machines. During the machining process, a solid block of material is clamped into a CNC mill and cut into a finished part. The range of material choices allows parts to be made with the desired material properties, and good tolerances yield parts suitable for form, fit and function testing.

CNC Turning

CNC Turning is a manufacturing process in which components or bars of materials are held in a chuck and rotated while a cutting tool removes material from the piece to create the desired shape. The cutting tool is controlled by a computer, which allows for accurate and repeatable processes.

Wire EDM, or electrical discharge machining, is a high-precision method for cutting nearly any electrically conductive material. KH Mold provides first-class Wire EDM services. Equiped Slow feeding Wire Cut machines with tolerance: 0.002mm and Mirror EDM machines with tolerance: 0.005mm we can manufacture even the most intricate parts with perfect accuracy and repeatability, whether you need prototypes, short production runs, or quantities in the tens of thousands.

Why Choose US